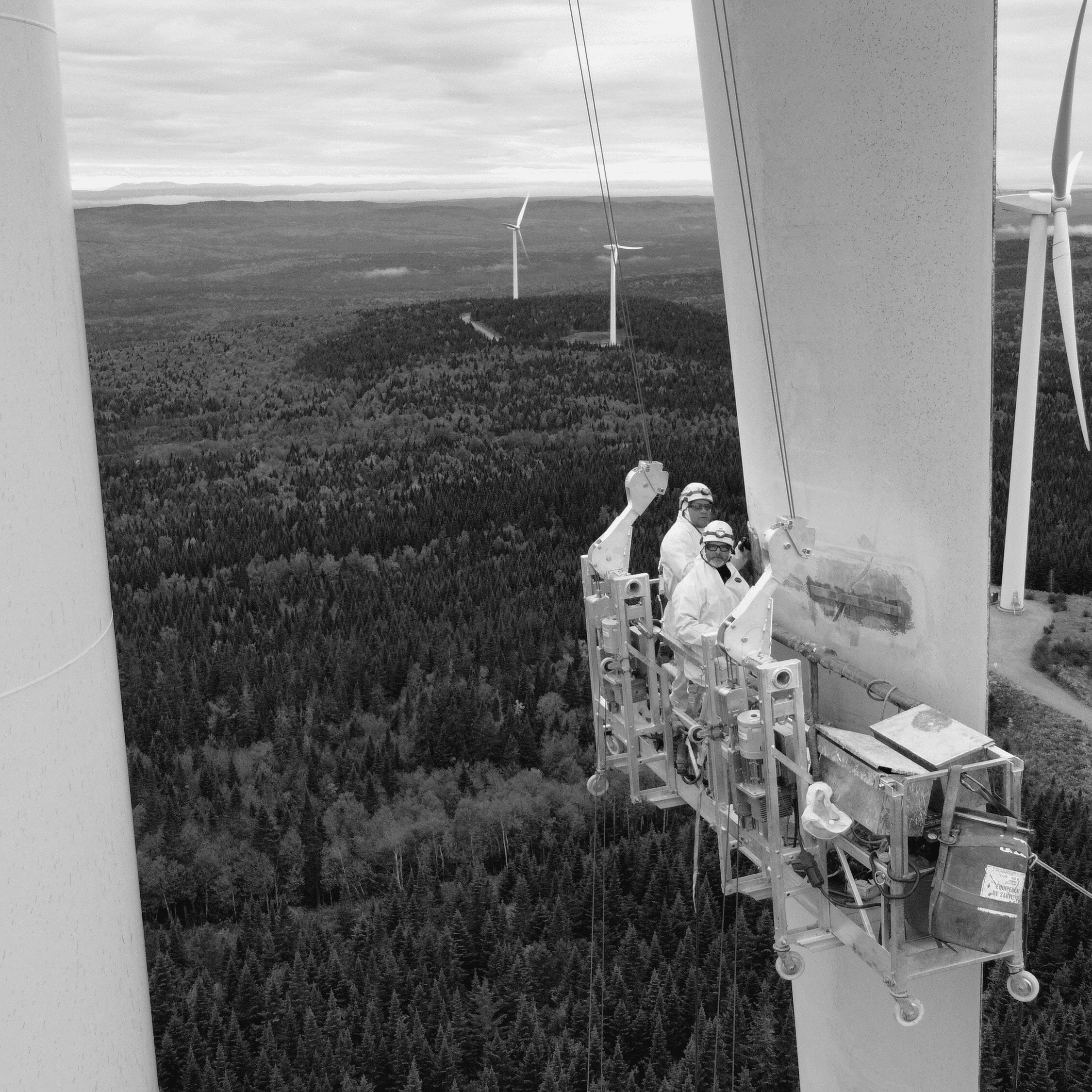

Our qualified and experienced technicians are able to recognize the different levels of composite material wear. They can conduct a 360-degree inspection of the parts, from inside the blade towards the outside, paying particular attention to the joints and moving parts, based on customer requirement.

Through a detailed inspection of each blade on each wind turbine, our blade inspection technicians can identify the problematic areas to target first. An inspection report provides details of the kind of work to be carried out.

High-quality wind turbine blade inspection services :

- Visual inspection of the blade interior

- Telescopic inspection of the blade exterior

- High-definition digital camera imaging

- Detailed inspection report and recommended maintenance